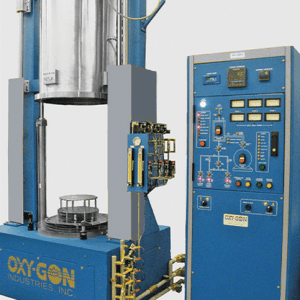

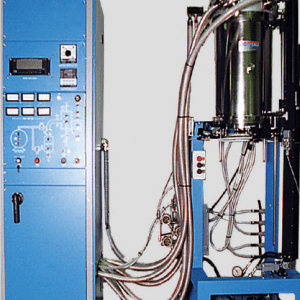

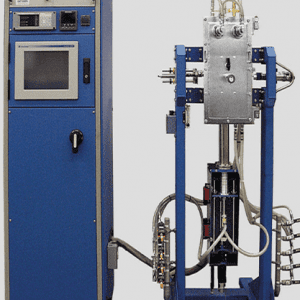

Molybdennum & Tungsten Furnace Elements

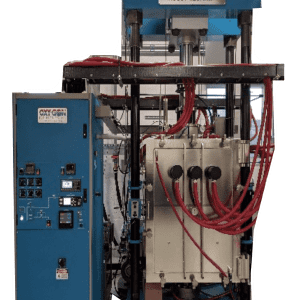

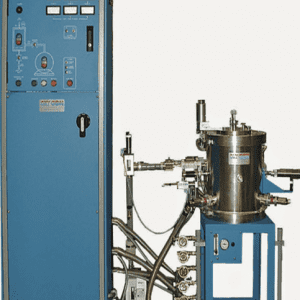

Molybdenum & Tungsten mesh and weave heating elements provide exceptional benefits for users of high temperature vacuum and atmospheric furnaces.

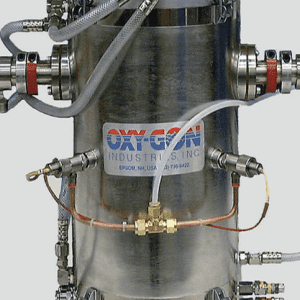

Oxy-Gon manufactures reliable high-quality molybdenum & tungsten elements in both mesh and weave configurations. These elements are meticulously hand crafted and undergo rigorous quality control to ensure that each is built to the highest standards.

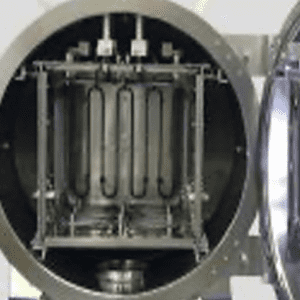

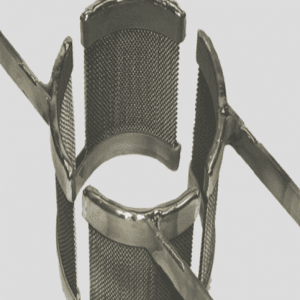

Oxy-Gon’s mesh and weave heating elements are made from continuous interlocked molybdenum & tungsten wire coils. When heated, each wire moves independently from its neighbor. The nature of the interlocked wire coils means that each element has built-in flexibility, especially compared to refractory sheet style elements. This largely eliminates mechanical and thermal stresses leading to considerably improved element life. These elements are available in both cylindrical and flat panel designs.

Standard element configurations

Circular Single Phase

– Split or one piece construction

– Split or one piece construction

Circular Three Phase

Flat Panel Three Phase