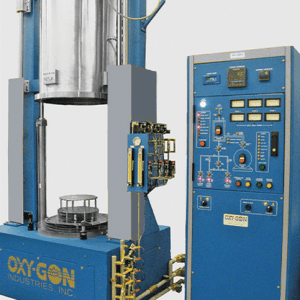

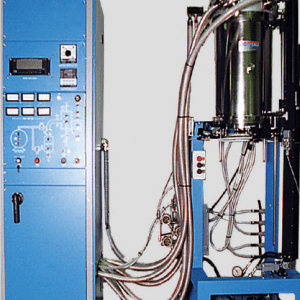

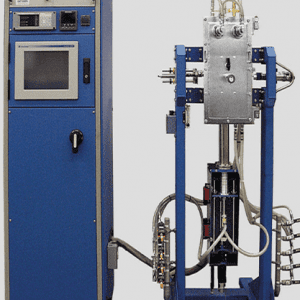

Top Loading Furnaces

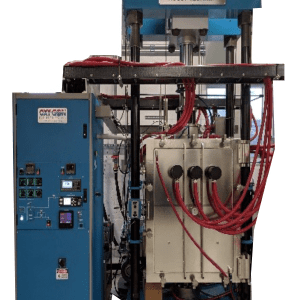

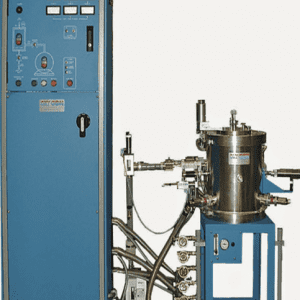

Oxy-Gon’s TC Series Top Loading Furnace is designed to provide years of continuous service while requiring a low investment cost.

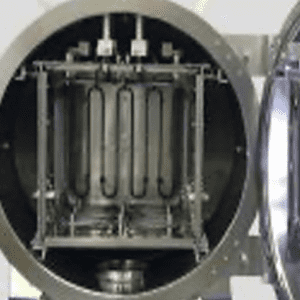

Designed for use in industrial or laboratory heat treating, sintering and brazing applications, our top loading vacuum furnace is capable of high temperatures and high vacuum, giving you the versatility you need for various production or R&D applications. And because of its top-loading functionality, our customers with laboratory and industrial applications enjoy extremely convenient and unobtrusive loading and unloading of fixtures and workloads.

Our top loading furnace system is designed to meet your needs right out of the box, with a wide range of optional components and accessories available as well. The basic Top loading furnace system includes the furnace assembly, power supply, heat zone, evacuation system, and inert gas system.

Our Products

Applications for our Hot Press Furnace Systems include:

Annealing

Brazing

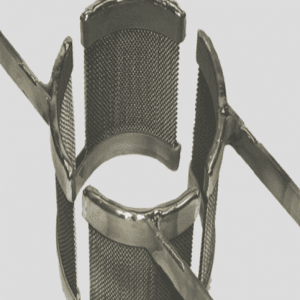

Diffusion Bonding

Ceramic Firing

Degassing

Glass Processing Studies

Melting

Sintering

Carbon Glass & Ceramic Composites

Custom Vacuum Furnace System Features

The furnace can be rated up to a maximum operating temperature of 2500° C (4,532° F) and will operate in vacuum, inert atmosphere, Nitrogen or Hydrogen.

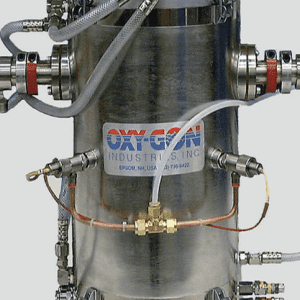

Constructed of double walled, 304L stainless steel

Each component is electropolished for the highest vacuum quality

Ports are incorporated into the heat chamber for a sight window

Water-cooled power feedthroughs

Graphite or refractory metal heating elements

Numerous available power supplies

Programmable process temperature controller

Separate over temperature limiter

Available recorders and data logging devices

Sensors available include thermocouple, optical pyrometers, and power transducers

Our Products

Why Choose Oxy-Gon as Your High-Temperature Vacuum Furnace Partner?

"Oxy-Gon has been an indispensable partner in our business. They worked very closely with us to provide an equipment solution that met our process needs, as well as our budget. Also, their response to questions regarding their equipment has been very accommodating. We’ve always been able to speak with a knowledgeable person right out of the gate, who has been able to quickly answer our questions. I would happily recommend this company to any customer in search of a high-quality, well supported piece of equipment."

G.D. , Chief Operating Officer

![]()

J.L. , PhD & Chief Technology Officer

![]()

"Quick replies to questions and great customer service is what first attracted us to Oxy-Gon, but their deep understanding of high-temp processing is what helped us pull the trigger on a furnace. Our relationship with Oxy-Gon has been and continues to be instrumental in moving our business forward."

H.S. , PhD, President & CEO

![]()

“Oxy-Gon did an outstanding job with the installation of our high temperature furnace. Their professionalism and thoroughness are greatly appreciated. We will be able to generate some exciting research results from our Oxy-Gon furnace.”

K.L., Ph.D. & Professor

![]()