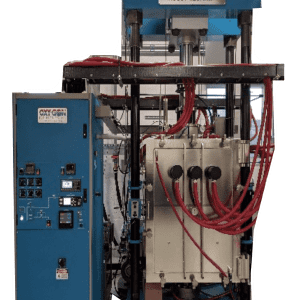

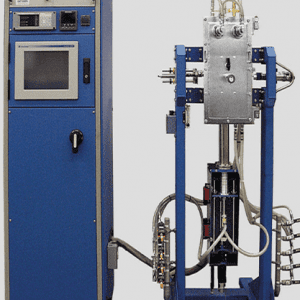

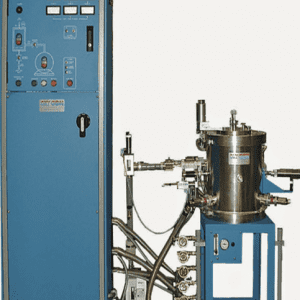

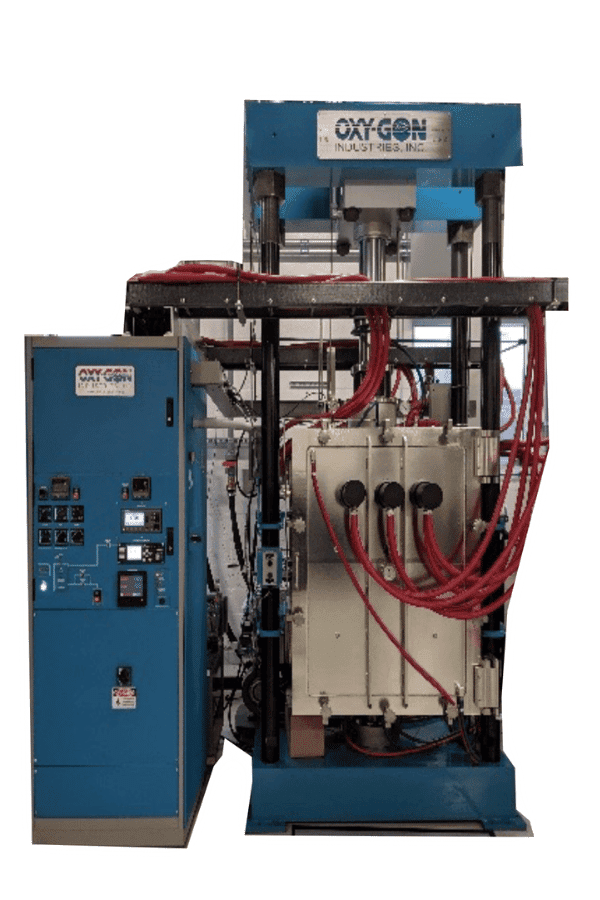

Hot Press Furnace Systems

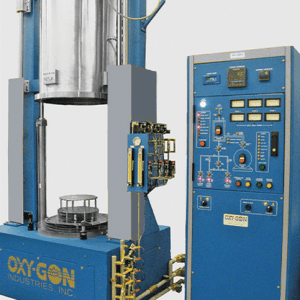

Oxy-Gon’s Hot Press Furnaces are “state of the art” design. They are constructed for ease of operation and will provide years of continuous service.

Combining Oxy-Gon’s industry experience with state of the art technology, our hot press furnace system delivers the features you need in a package that’s easy to operate, clean, and maintain.

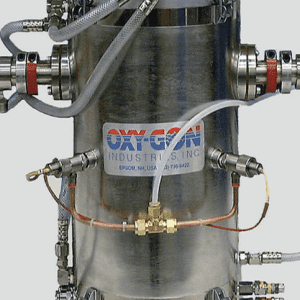

Our Oxy-Gon Hot Press Furnace is designed to give you years of reliable service with all of the features that make your job easier, like stainless steel construction, easy temperature control, and available recorders and data logging devices. Other features include:

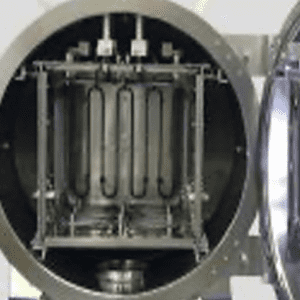

- Double walled chamber and front door

- Electropolished components for higher vacuum quality

- Water cooled power feedthroughs

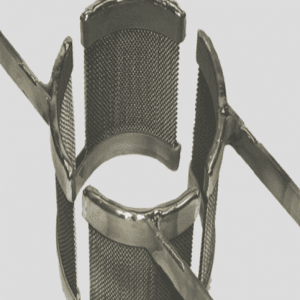

- Easy loading and retrieval of die and punch assemblies

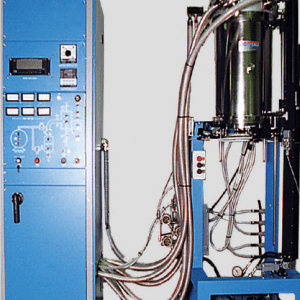

- Multiple available power supplies

- Programmable process temperature controller

Our Hot Press Furnace Systems are available within the following parameters:

Force: 25 to 100 Tons

Hot Zone Sizes: To accept Die diameters of 1″ to 12″ and lengths to 12″

Heating Elements: Molybdenum, Tungsten Mesh, High Purity Graphite; all with appropriate Heat Shield Insulation

Temperature: 500C to 2500C

Atmospheres: Gas at 2 PSIG, Rough or High Vacuum, 10 ^-2 Torr to 10^-6 Torr