Crystal Growth Furnaces

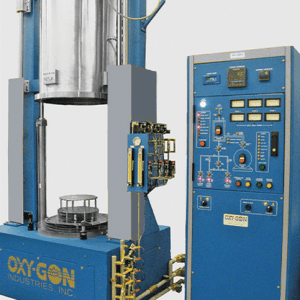

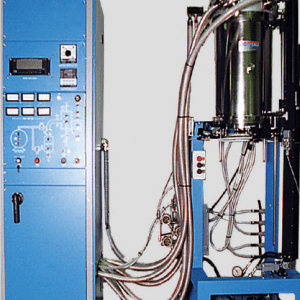

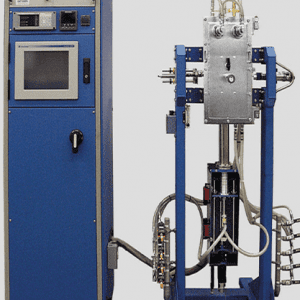

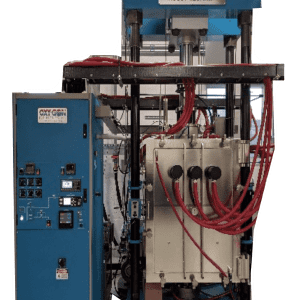

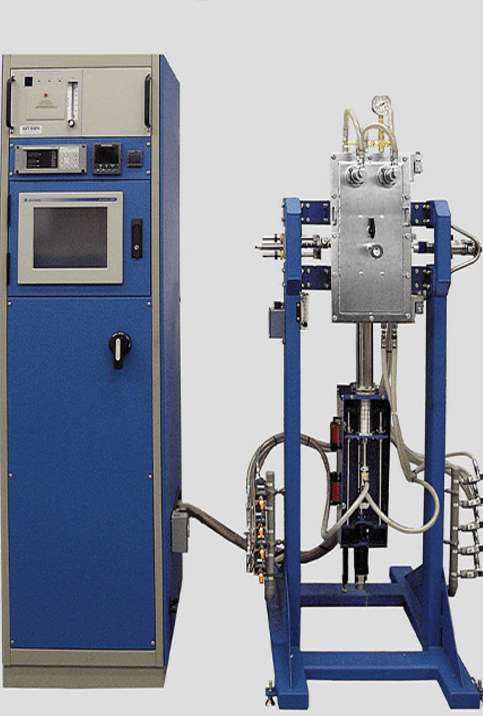

Oxy-Gon’s Modified FR Series Furnaces are configured specifically for Crystal Growth Systems by Bridgman-Stockbarger and Directional Solidification Techniques.

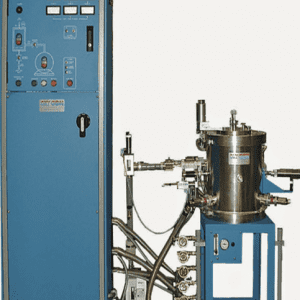

Oxy-Gon designs and manufacturers these systems for ease of operation and reliability to provide years of continuous service. The perfect solution for research and university laboratories.

Our crystal growth furnaces use our Crystal Pullers and/or translation mechanisms, specifically engineered to provide smooth translation during the crystal growth process using micro-stepping motors that are controlled by the main PLC. Rotational stages can be added to the crystal pullers as well.

Designed specifically for Crystal Growth Systems by Bridgman-Stockbarger and Directional Solidification Techniques.

- Our crystal growth furnaces also provide a variety of heat zones for different applications.

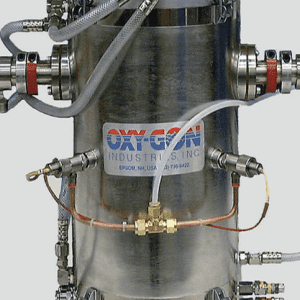

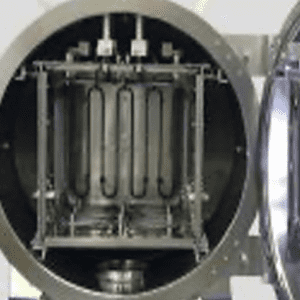

- Our single zone refractory metal heat zone for a Bridgman Crystal Growth Furnace System drops into a separate water-cooled vacuum chamber.

- Our single zone heat zone configuration incorporates a water-cooled plate that facilitates establishing steeper axial gradients for directional solidification processes.

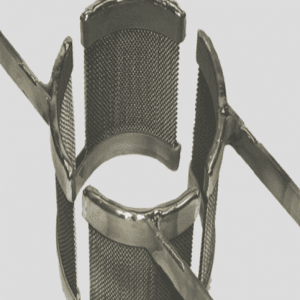

- Our crystal growth furnace with a custom Graphite heat zone, that has been modified to include a retractable pedestal for rapid thermal processing. Graphite heat zones are typical for Czochralski Crystal Growth Furnace Systems. Similar graphite heat zones are available for directional solidification process up to 2800°C.

- The basic crystal growth furnace system includes the furnace assembly and choice of heat zone, temperature controls and power supply, crystal puller—translation mechanism, evacuation system, and inert gas supply.