LATEST NEWS

Vacuum Furnaces by Oxy-Gon:

Your Gateway to High-Temperature Processing.

After 35+ years in the industry, we are privileged to work with production in private industries, colleges, universities, and government laboratories worldwide. Our State-of-the-art furnaces are used in Aerospace, Aviation, Communications, Defense, Energy, Materials, Medical, Nuclear, Optics, R&D and most of the world’s technology that surrounds us all. Our partners trust Oxy-Gon to design, build, and service high-temperature vacuum furnaces that are used in many different processes.

Annealing

Brazing

Ceramic Composites

Ceramic Firing

Crystal Growth

Diffusion Bonding

Degassing

Extensometry

Glassy Carbon

Glass Processing Studies

Graphitization

Hot Pressing

Melting

Quenching

Sintering

Tensile Testing

Discover the Difference Oxy-Gon Can Make

What Are Our Customers Saying?

The BF Series Bell Furnace is designed to optimize space, performance, and flexibility for a wide variety of heat treating, laboratory, and production applications. On top of this, the all-stainless steel, tungsten, or molybdenum hot zones provide an environment particularly fitting for applications that require minimal particulate contamination, ranging from semiconductor production to applications involving medical devices.

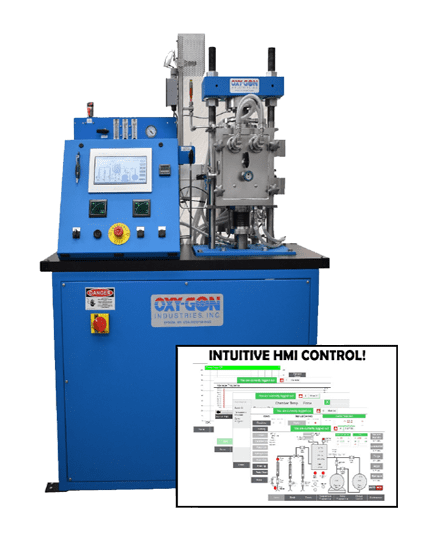

Bench Top (Hot Press) Furnaces

Perfect for university and research laboratories, the benchtop hot press is rated up to a maximum operating temperature of 2000°C and will operate in vacuum, argon, nitrogen and forming gas (95%N2/5%H2) atmospheres.

The basic furnace system includes the furnace assembly, power supply, heat zone, evacuation system, press frame, hydraulic system, and inert gas supply.

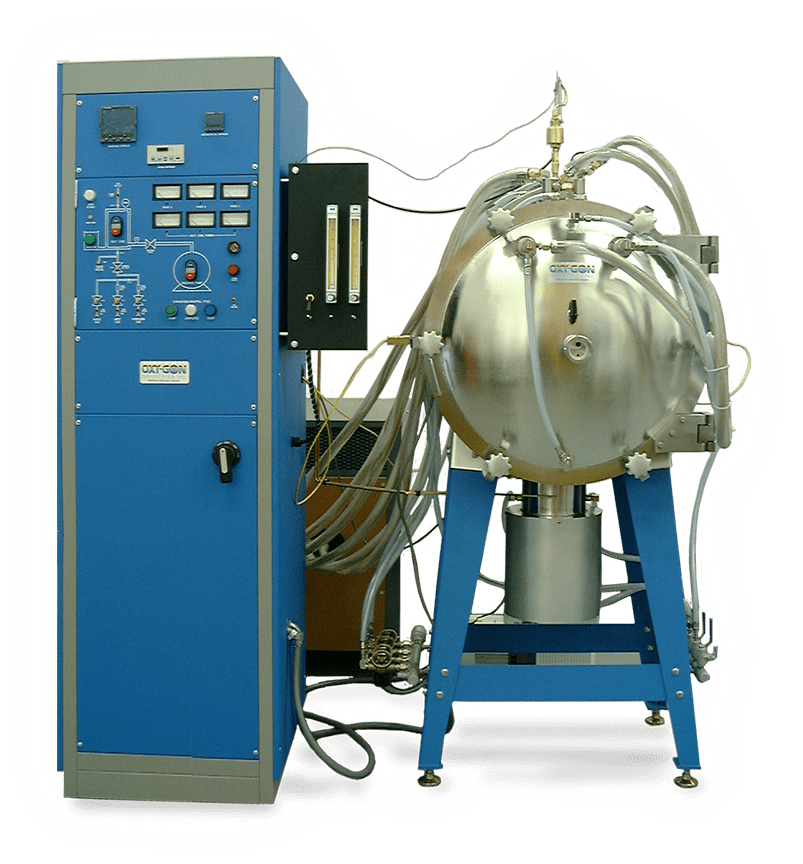

Bottom Loading Furnaces

Whether you’re looking to enhance your processes with more effective heating or simply need to replace an existing sintering furnace, our furnaces are built to perform and to last. By combining precision manufacturing to ensure the best vacuum quality as well as a number of features to ensure ease of use, we’re positive that an Oxy-Gon bottom loading furnace is an effective and competitively priced solution for your business.

Our crystal growth furnaces use our Crystal Pullers and/or translation mechanisms, specifically engineered to provide smooth translation during the crystal growth process using micro-stepping motors that are controlled by the main PLC. Rotational stages can be added to the crystal pullers as well.

End Loading Tube Furnaces

Oxy-Gon’s EC Series End Loading Furnace is designed to provide years of continuous service while requiring a low investment cost. Oxy-Gon manufactures high-temperature, end loading tube furnaces in a wide variety of configurations for industrial and laboratory applications. In fact, we designed our end loading tube furnaces with versatility in mind, including a wide range of temperatures, programmable temperature controls, and other helpful features.

Fiber Drawn Vacuum Furnaces

The Oxy-Gon Fiber Draw Furnace Series are designed to minimize the generation of particulates and to maximize the production of quality fiber. Oxy-Gon’s reliable furnaces for fiber drawing are known for their simplicity, efficiency, and high-quality materials. Our series of fiber draw furnaces are easier to operate and maintain, providing you with a reliable tool that delivers the same level of high-performance day in and day out.

Combining Oxy-Gon’s industry experience with state of the art technology, our Hot Press Furnace is designed to give you years of reliable service with all of the features that make your job easier, like stainless steel construction, easy temperature control, and available recorders and data logging devices.

Molybdenum | Tungsten Furnace Elements

OXY-GON manufactures reliable high-quality Molybdenum elements in both mesh and weave configurations. These elements are meticulously hand crafted and undergo rigorous quality control to ensure that each is built to the highest standards.

Physical Test Furnaces

Implementing our furnace expertise with the test frame technology, the physical test furnaces allow samples to be tested for compression strength, deflection, fatigue, multi-axial testing, tensile strength, torsional strength, etc. using various temperatures and controlled atmospheres.

Oxy-Gon is your best choice for gas purification laboratory furnaces. Designed for those needing a small lab furnace, our OG-120 gas purification furnace is a completely self-contained solution that you can rely on to purify inert gases to less than 1PPB of oxygen or better. In addition to removing oxygen, the OG-120 gas purification furnace also removes Nitrogen, Carbon, and Water Vapor, making it a comprehensive solution for a wide variety of lab and production applications.

General Purpose Furnaces

Designed and manufactured to deliver effective, efficient, and homogenous heating throughout, our general purpose ceramic furnaces are used in numerous industrial applications with outstanding results. In fact, to ensure each furnace has the best possible vacuum quality, every component is electropolished for better vacuum pressures, outgassing rates, and pumping speeds.

Graphite Hot Zones

Competitively priced graphite hot zones are available for any vacuum or inert atmosphere furnace. These elements and insulation packs can operate up to 3000°C (depending on vacuum level), are more energy efficient then full metal hot zones and can have a longer lifespan with proper maintenance.

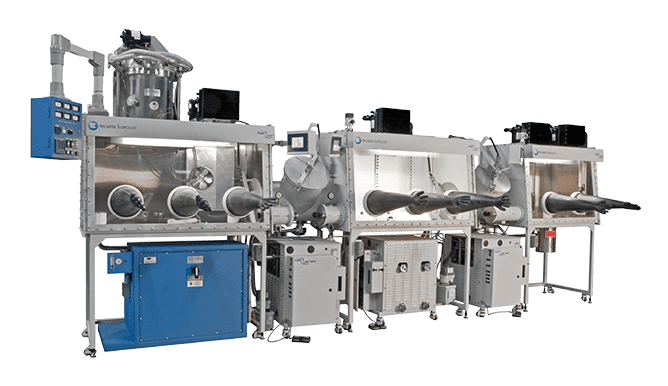

Top Loading Vacuum Furnaces

Our top loading furnace system is designed to meet your needs right out of the box, with a wide range of optional components and accessories available as well. The basic Top loading furnace system includes the furnace assembly, power supply, heat zone, evacuation system, and inert gas system.