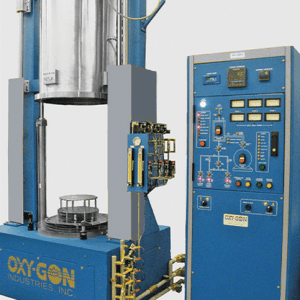

General Purpose Furnaces

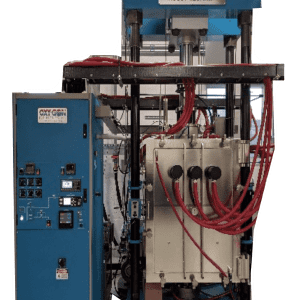

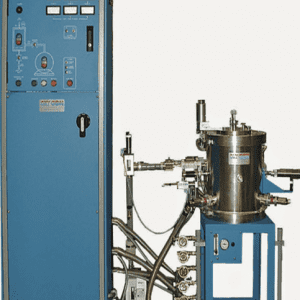

Oxy-Gon’s FC Series General Purpose Ceramic Furnaces are designed to provide years of continuous service while requiring a low investment cost.

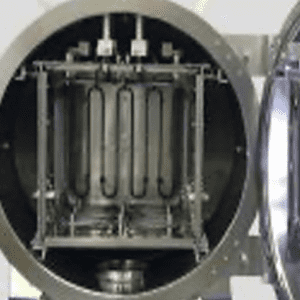

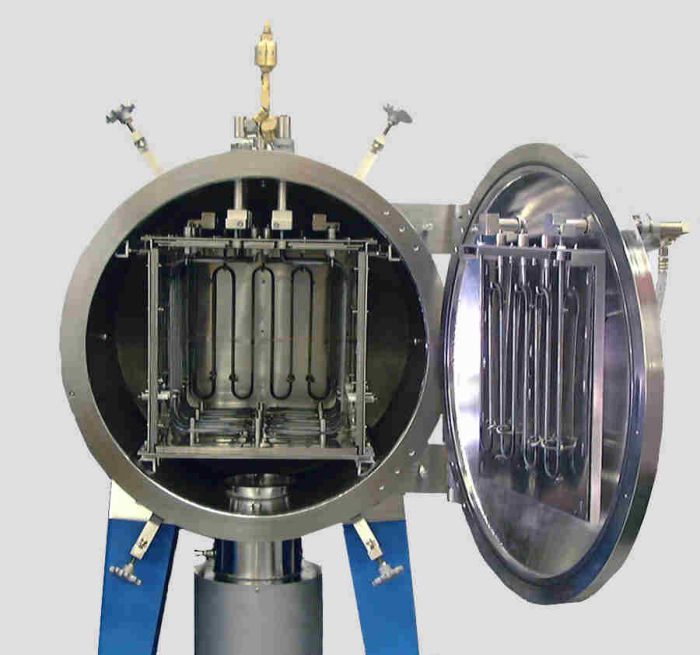

Designed and manufactured to deliver effective, efficient, and homogenous heating throughout, our general purpose ceramic furnaces are used in numerous industrial applications with outstanding results. In fact, to ensure each furnace has the best possible vacuum quality, every component is electropolished for better vacuum pressures, outgassing rates, and pumping speeds.

A Ceramic Furnace Designed for Versatility

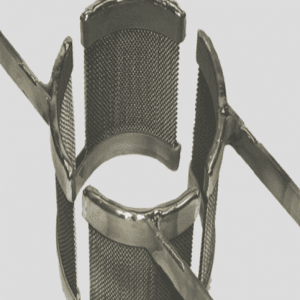

Our general purpose ceramic furnaces were also designed for durability and versatility. They can operate to a maximum temperature of 2500°C (4532°F). The heating elements in our general purpose ceramic furnaces are located on all sides of the heat zone for exceptional temperature uniformity. Plus, depending on your application and the operating temperature of the unit, the element and shield packages can be supplied in Graphite, Molybdenum, Tantalum, or Tungsten.

Moreover, they will operate in a vacuum, inert atmosphere, nitrogen, and wet or dry hydrogen. Programmable temperature controls and a fully automatic pumping system saves time and improves efficiency. And it’s available with various power supplies. There are also a wide variety of add-ons and value-added features.