The Oxy-Gon FC Series General Purpose Ceramic Furnace

The FC Series General Purpose Ceramic Furnaces are designed to provide years of continuous service while requiring a low investment cost.

Regardless of your industry or application, whether you’re dealing with brazing, sintering or metal processing, if it calls for a furnace our FC series furnace gets the job done.

Our Products

Features Include:

Rugged construction

Maximum operating temperature of 2500°C (4532°F)

Will operate in a vacuum, inert atmosphere, nitrogen, and wet or dry hydrogen

Various available power supplies

Programmable temperature control

Fully automatic pumping system

And more...

A Ceramic Furnace Designed for Versatility

The FC Series General Purpose Furnaces are designed to provide years of continuous service. To do that, we manufacture them with the state-of-the-art features you need, combined with many small details we’re sure you’ll appreciate, like rugged construction, a streamlined user-interface, and outstanding flexibility – all at a competitive price. Should you require any sort of additional attachments or features, no problem. A wide variety of add-ons and value added features are available as well.

Applications for this ceramic furnace include:

Annealing

Brazing

Diffusion Bonding

Metalizing

Sintering

Heat Treating

Casting

The basic furnace system includes the following components:

Furnace Assembly

Heat Zone

Power Supply

Evacuation System

Inert Gas System

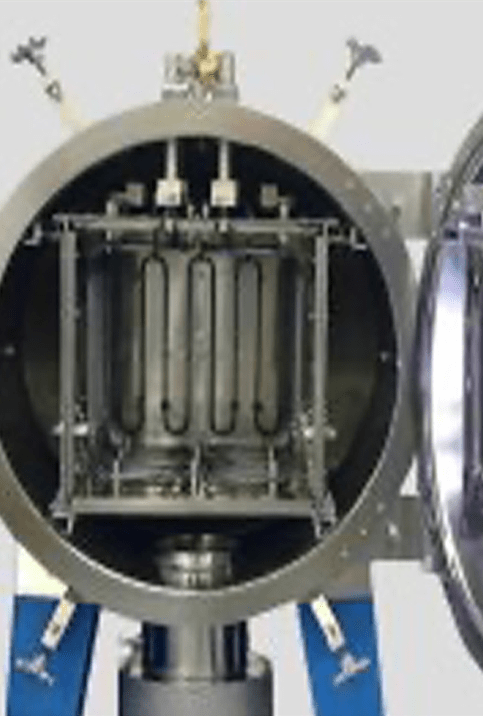

Furnace Assembly

For all of our furnaces, the chamber, front door, and rear cover are double walled, 304L stainless steel — making them extremely sturdy. To ensure that each furnace has the best possible vacuum quality, every component has also been electropolished to give the furnace a smoother surface for better vacuum pressures, outgassing rates, and pumping speeds.

Ports are incorporated in the chamber and front door for a sight window, thermocouples, or an optical pyrometer. Power for the heating elements is supplied through power feedthroughs located in the the chamber. The power feedthroughs are Nickel plated.

Heat Zone

The heating elements in our FC Series furnaces are located on all sides of the heat zone for exceptional temperature uniformity. Depending on your application and the operating temperature of the unit, the element and shield packages can be supplied in Graphite, Molybdenum, Tantalum, or Tungsten.