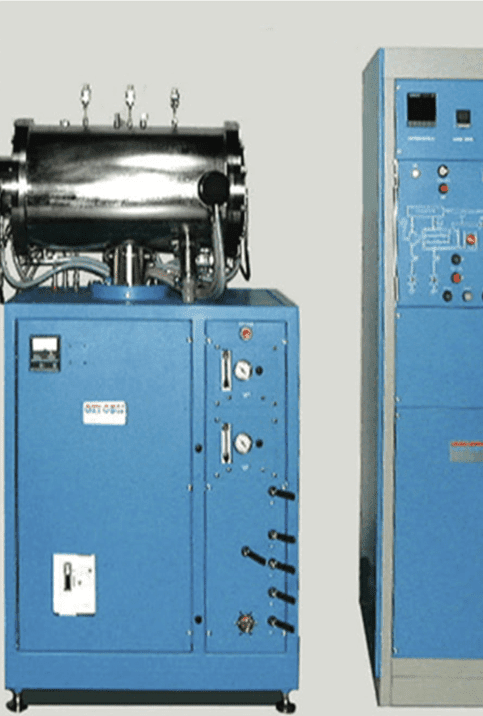

The Oxy-Gon EC Series End Loading Tube Furnaces

The EC Series End Loading Furnace is designed to provide years of continuous service while requiring a low investment cost.

Every one of our furnaces is manufactured with ease of use and reliability in mind. For every product, we take into consideration the level of performance and quality you require from an industrial furnace manufacturer and we add the convenient and valuable features that you can’t expect from many others . In the end, what you get is a better furnace and a better end result, all at a competitive price.

Our Products

Programmable temperature controls

Over temperature limiter

High grade graphite heating element

Heat zone sizes ranging from 2" ID to 6" ID and up to 48" long

Fully automatic PLC controlled pumping systems

Compatible with Inert Gas or Nitrogen

Compatible with Dry Hydrogen with optional system

Available recorders and data loggers

Available ceramic muffle kits for oxidizing/corrosive atmospheres

And more...

A High Range of Temperatures for a Wide Range of Applications

As an industrial furnace manufacture, we understand that the number of applications for industrial (and laboratory) furnaces is large. To meet the many needs of our customers everywhere, we’ve manufactured our end loading tube furnaces with versatility in mind. That means a wide range of temperatures, programmable temperature controls, and other helpful features.

Tube furnaces from Oxy-Gon are rated for a maximum operating temperature of 2500°C (4532°F) and will operate in vacuum, inert atmospheres, or Nitrogen. Common applications for the end loading tube furnace include:

Annealing

Brazing

Melting

Sintering

Heat Treating

The basic tube furnace system includes the following components:

Furnace Assembly

Power Supply

Heat Zone

Evacuation System

Inert Gas System

Furnace Assembly

The chamber of this tube furnace is double walled, 304L stainless steel and is electropolished to attain the highest vacuum quality. The power feed throughs, covers, and access lid are all nickel plated copper construction. Ports are incorporated in the chamber and/or access lid for a sight window, thermocouples, or an optical pyrometer.

Heat Zone

The element and insulation are high grade graphite. Heat Zone sized range from 2″ ID to 6″ ID x up to 48″ long with a muffle tube. Without the muffle tube, the size ranges from 2″ ID to 12″ ID x up to 48″ long. Other sizes are available upon request.

Power Supply

Power supplies can be supplied with any of the following characteristics: Single (1) or three (3) phase, 208, 380, or 480 volts, and 50 or 60 hertz. A typical power supply incorporates the following components: Stepdown tranformer, SCR power controller, circuit breaker, contactor, pushbuttons, and indicator lights. All components are wired and housed in a free standing cabinet.

Temperature Control

Depending on the customer’s requirements, OXY-GON INDUSTRIES, INC. can incorporate as a part of the furnace system the programmer/controllers, recorders, and temperature control devices (i.e. thermocouple, optical pyrometer, or power transducer).

Pumping System

Manual through fully automatic (PLC control) pumping systems can be provided for the range of 10-20 Millitorr (rough vacuum with mechanical pump) through 10 -5 Torr (high vacuum with diffusion and mechanical pumps). Our typical standard system is automatic and consists of a diffusion or turbomolecular high vacuum pump, mechanical pump, the necessary valving, and a vacuum gauge controller. The system will consistently operate in the 10-5/ 10-6 Torr range.

Inert Gas/Nitrogen System

To allow operation using inert gases or Nitrogen, a kit which includes inlet/outlet valves and a pressure/ vacuum gauge is supplied as well as a glovebox interface kit.