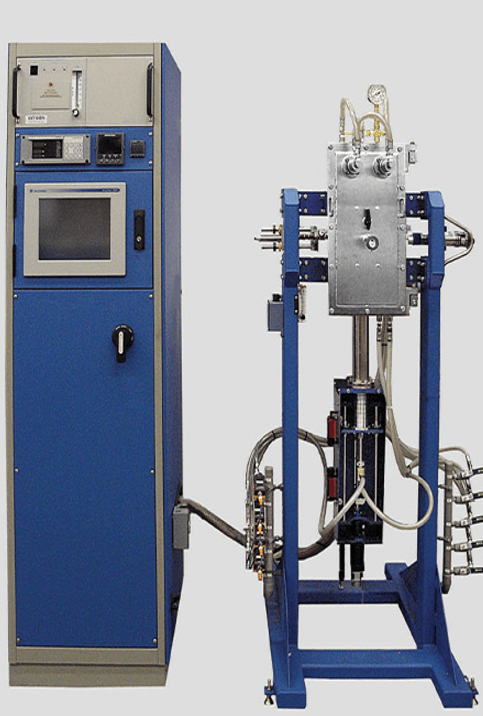

High Temp Universal Application Furnace

FR Series

High Temp FR Series Universal Application Furnaces are designed to provide years of continuous service while requiring a low investment cost.

One of our most popular furnaces is the high temp FR series Universal Application Furnace, which has been designed to provide years of continuous service while requiring a low investment cost. This furnace can be rated up to a maximum operating temperature of 2,500 degrees C (4,532 degrees F) and will operate in vacuum, inert atmosphere, Nitrogen or Hydrogen.

Our Products

The Universal Application Furnace: All the Furnace You Need

Whether you need a hot press furnace, a crystal growing furnace, or a diffusion bonding furnace, there’s a good chance that our High temperature universal application furnace will fit your needs.

Annealing

Brazing

Diffusion Bonding

Extensometry

Hot Pressing

Melting

Quenching

Sintering

Tensile Testing

Basic High Temperature Furnace System includes the following components:

Furnace Assembly

Heat Zone

Power Supply

Evacuation System

Inert Gas System

Additional features and specifications are also available

Furnace Assembly

Our high temperature furnace is assembled with strength and longevity in mind, with a chamber, front door, and rear cover manufactured with double walled, 304L stainless steel. On top of this, each component is electropolished to attain the best vacuum quality possible.

Ports are incorporated into the high temperature furnace’s chamber and front door to accommodate a sight window, thermocouples, or an optical pyrometer.

Power to the rear of the element is supplied by silver plated copper power feedthroughs located on the rear cover, with power to the front element through silver plated copper knife switches. This allows us to eliminate power cables that are typically mounted on the front door.

The Heat Zone

When it comes to the design of your high temperature furnace, flexibility is one of our primary goals. With that in mind, one half of the element and the side and top shield packages are mounted on the front door of the furnace. This provides easy access to the work area of the heat zone, which can range from one inch diameter by one inch high up to four inches by four inches.

Depending on the operating temperatures of the unit and your common applications, the element and shield packages are available in Molybdenum, Tantalum, Tungsten, or Graphite.